Fire classification of cables (part 2) – European classification of cables constituting construction products

In 2011, the European Union commenced works to determine fire safety criteria and classify products used in the construction sector. The Construction Product Directive (CPD) was drawn up. As a result of these works, the Construction Product Regulation (CPR) document was approved in July 2013. In June 2016, the European Committee published the following standard: hEN50575 Power, control and communication cables. Cables for general applications in construction works with a specific fire resistance class. The final effective date for this standard in member states is the second half of 2017. Due to the fact that this document was published in the form of a European Union directive, it is not only a recommendation, but a mandatory regulation. It imposes on member states an obligation to draw up a declaration of conformity and affix a marking in accordance with CE, with regard to fire structures and parameters. Designers must comply with the directive when drawing up design documents. Cables must be installed in accordance with the directive, thus it applies to the users as well.

The European standardisation bodies, CEN and CENELEC, received an authorisation from the European Committee to draw up a harmonised standard concerning power, control and communication cables intended for permanent installation in construction works. Cables are divided into different classes depending on their reaction to fire – tested in accordance with standards on tests arranged on the basis of such an authorisation.

Euro class | Testing methods | Classification criteria | Additional criteria |

A | EN ISO 1716 Gross calorific potential | PCS ≤ 2.0 MJ/kg |

|

B1 | EN 50399 (30 kW) | FS ≤ 1.75 m | Release of smoke, flaming droplets/particles and acids |

Fire propagation | THR1200S ≤ 10 MJ HRR = 20 kW FIGRA = 120 Ws-1 | ||

EN 60332-1-2 | H = 425 mm | ||

B2 | EN 50399 (20.5 kW) | FS ≤ 1.5 m THR1200S ≤ 15 MJ HRR = 30 kW FIGRA = 150 Ws-1 | Release of smoke, flaming droplets/particlaes and acids |

EN 60332-1-2 Fire propagation | H = 425 mm | ||

C | EN 50399 (20.5 kW) | FS ≤ 2.5 m THR1200S ≤ 30 MJ HRR = 60 kW FIGRA = 300 Ws-1 | Release of smoke, flaming droplets/particles and acids |

EN 60332-1-2 | H = 425 mm | ||

D | EN 50399 (20.5 kW) | THR1200S ≤ 70 MJ HRR = 400 kW FIGRA = 1300 Ws-1 | Release of smoke, flaming droplets/particles and acids |

EN 60332-1-2 | H = 425 mm | ||

E | EN 60332-1-2 | H = 425 mm |

|

F | not meeting the requirements for class E |

|

|

Table 1. Fire class designation of cables in accordance with the hEN 50575 standard guidelines.

FIGRA – fire growth rate defined as a quotient of HRRsm30 (excluding the ignition source impact) and time. Threshold values are as follows: HRRsm30 = 3 kW and THR = 0.4 MJ. THR – total heat release (HRRsm30) between the beginning and the end of test (excluding the ignition source impact). HRR – heat release rate averaged with a 30-second moving average. FS – flame spread (damage range).

Currently, the Polish regulations concerning building systems are included in two main documents. The first one is the Regulation of the Minister of Infrastructure of 12 April 2002 on technical conditions of buildings and their location. Chapter 8 (electric systems) describes basic components of an electric network, fire and lightning system, evacuation lighting and maintenance of power supply continuity of devices intended for fire protection. The second document is a standard: SEP N SEP-E-005 Selection of electric cables for supplying fire protection devices which must remain functional during a fire, in which the terminology and principles of power supply and protection of devices, fire protection and emergency lighting are specified. Appendix A describes the fire environment and phenomenon. However, neither of these documents specifies requirements concerning cables in general and low-voltage electric systems.

Installation of a fire alarm system or a sound alarm system is more specifically regulated by laws and recommendations published by the Research and Development Centre for Fire Protection, but they do not refer to low-voltage cables used in building systems, e.g. structural cables, telecommunications cables or cables used for video surveillance, while there are many of them in hotel systems, office buildings or mass event buildings.

As a result of the tests and fire growth modelling in buildings, hazards and factors affecting the evacuation speed were listed:

- flammability,

- flame propagation,

- smoke emission,

- leak release,

- heat release.

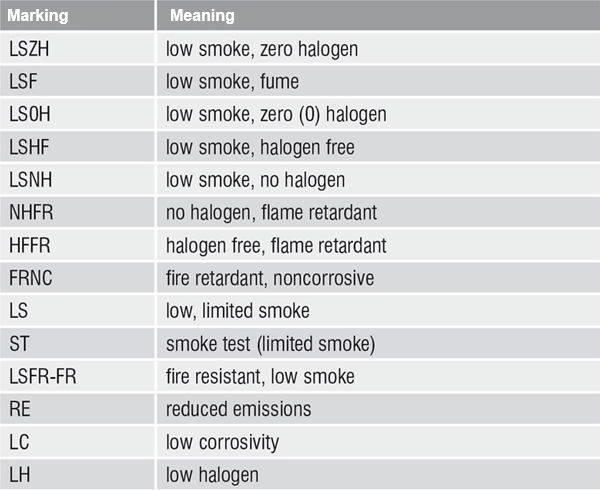

At present, resistance to some material properties or phenomena is marked with characters on communication and telecommunications cables – LSOH, LSZH, LSHF, FRNC-C, LSFR-FR or other. Applied English markings are given in table 2.

Table 2. English markings of resistance to some properties of communication and telecommunications cable properties.

These markings refer to the above additional criteria – not to the basic ones, which should be additionally marked as below:

- smoke release – s1, s2,

- release of flaming droplets/particles – d1, d2,

- release of acids – a1.

A fire class of a cable should be marked in accordance with the guidelines of hEN50575 (table 1). Different reactions of cables to fire were taken into consideration in the classification. Class A cables are inflammable, class F cables do not meet the requirements for Class E cables. The remaining classes: ACA, B1CA, B2CA, CCA, DCA, ECA, FCA , where CA means Euro class.

Methods of testing cables and cords and their reaction to fire are described in the EN 50399:2011+A1:2016 standard. All manufacturers of cables/cords are obliged to carry out tests in independent accredited research laboratories to obtain relevant certificates confirming the fire resistance class. Such certificates constitute grounds for issuing a Declaration of Performance. The mandatory date for manufacturers is 1 July 2017, all cables must have a CE certificate afterwards.

Member states of the European Union should prepare a current classification of buildings, according to which requirements for respective types of applied cables could be determined. One can assume that the following building classes will be separated:

- residential buildings (with additional division according to different heights),

- high and high-rise buildings,

- office buildings,

- shopping malls, entertainment centers,

- restaurants and hotels,

- hospitals and care centers,

- data centers, server rooms.

For each of the mentioned type of buildings a required cable Euro class must be determined, e.g. for data centers – B2 with additional parameters – s1, d1, a1. It is necessary to separately describe common parts, such as evacuation routes which, due to their functions, should have proper resistance to fire.

IT solutions and electric infrastructure consisting of cable systems constitute a basis for a smart building. Such buildings may house offices, data centers, production plants, etc. Cables containing flammable materials are often used which poses a risk of fire propagation. Cables must not only fulfil their role during normal operation, but also not to create an additional hazard in the event of a fire. The risk can be minimised through the application of low fire-hazard cables.

With the introduction of pan-European reaction-to-fire classes, architects, planners and operators have clear regulations for cable use.

In order to reach a higher fire safety level, cable manufacturers recommend to:

- upgrade the fire safety level in the entire building by using low fire-hazard cables,

- use B2CA class cables in special-purpose buildings which must meet very high safety requirements (e.g. in hospital, nurseries),

- use CCA class cables in buildings which must meet very high safety requirements (e.g. in administration or office buildings).

All member states of the European Union are responsible for implementation of safety standards in buildings which must meet very high safety requirements and adaptation of current safety regulations.

The advantages of low fire-hazard cables will not be noticeable in a daily life, similar to airbags in vehicles. They will reveal their functions during a fire.

Drawn up by

Michał Piechulek, MSc

This article contains information included in the ‘Low fire-hazard cables improve safety’ document published on 15 September 2015 by ZVEI – Zentralverband Elektrotechnik- und Elektronikindustrie e.V. (http://www.zvei.org/Publikationen/Low-fire-hazard-cables-improve-safety-..., as of 19.07.2016).

The article was originally published in the ‘Zabezpieczenia’ journal, no. 5/2016.